Load Restraint Bars

Load Restraint Bars also known as cargo bars or ratchet bars are primarily used within commercial vehicles to secure pallets, boxes, crates and general cargo. Our shoring bars are specifically designed to prevent loads moving during transportation reducing the risk of injuries and damage to goods and vehicles.

Our range of Load Restraint Bars

We offer a wide range of load restraint bar types including spring loaded shoring bars which insert into 1806 anchor track, ratcheting cargo stay bars which secure loads in box bodied vehicles, trailers and shipping containers with no track fitted. Garment bars for clothes, E-type decking beams for additional load bearing decks whilst our heavy duty steel load bars and cups offer ultimate load containment for HGV’s and trailers with up to 3500kg load capacity.

Size and Adjustability

Our load restraint bars are available in range of shapes, sizes and lengths from 1.0metre to 2.9metres including bespoke made to measure shoring bar, garment bar and rigid steel bar options.

Material and Construction

Titan load restraint bars are constructed from heavy duty steel with bright zinc plating for enhanced strength, durability and corrosion resistance. Aluminium shoring bars and cargo stay bars are 40% lighter than steel bars which can make a difference when considering a vehicles overall internal weight/pay load.

Weight Capacity

The load capacity or ultimate load limits of our shoring bars range from light duty 460kg up to heavy duty 3500kg when spread equally across the bar. When choosing shoring bars it’s essential that the bar(s) can withstand forces equivalent to 100% of the entire weight of the load in a forward direction and 50% the weight of the load in sideways and backward direction.

Mechanism and Ease of Use

Spring loaded shoring bars are easy to install into 25mm hole 1806 track as the sprung loaded end simply compresses, allowing the operator to slot the bar in and out. Cargo stay bars have a specially designed ratcheting mechanism allowing for quick and easy installation into box bodied vehicles, trailers and shipping containers.

Compatibility

Shoring bars are compatible with various vans, trucks and trailers equipped with internal load tracks such as 1806 Q track, combi E-type track, keyhole, and universal E-track ensuring versatile load restraint solutions. Ratcheting cargo stay bars are suitable for box bodied vehicles, trailers and shipping containers where no internal track is installed as the bar extends against between the two surfaces to stabilise the load.

Safety Features

Cargo stay bar safety features include padded rubber feet which provide secure grip on walls preventing slipping during transit whilst the ratchet locking mechanism prevents accidental release during transit. Shoring bars telescopic design allows for precise adjustments to fit securely between cargo area walls, ensuring optimal tension. Manufactured from heavy duty steel and aluminium prevents bars breaking under force providing cargo safety and security.

Applications

Load shoring bars and cargo stay bars are commonly used with transport, logistics, warehousing, retail and distribution for securing cargo within trucks, trailers, vans and shipping containers to prevent loads shifting during transit. Examples of loads secured by shoring bars include palletised goods, loose boxes/crates, roll containers, cages, furniture and industrial equipment.

Care and Maintenance

It's essential to inspect shoring bars for rust, damage, end fittings and locking mechanisms before and after use. Clean off dirt, grease and moisture to prevent corrosion, especially on steel bars. Handle the bars carefully, avoid dropping or overloading and store them in a dry environment, when possible to ensure their longevity.

Installation Guide

To install spring loaded shoring bars or cargo stay bars simply extend or shorten the bar to the desired length. Ensure the bar fits firmly between the load tracks/walls of the vehicle or trailer. When positioning ensure the bars are level and located at the same height at both ends and if needed adjust the tension by pressing or releasing the ratcheting mechanism on the cargo stay until the bar is secure.

Standards and Guidance

All our products have been manufactured to the highest quality standards to ensure we are supplying safe and secure load securing systems. Click here for more information on official government guidance on securing loads.

Accessories and Add-ons

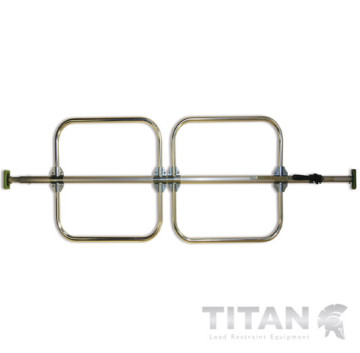

Rigid steel load bars fit within heavy duty steel load cups at either ends of the bars which in turn slot into 1806 load track. Both the steel load cups and 1806 load track accessories can be purchased separately.

Pricing Information

£2.99 to £99.99 (excluding VAT).

Shipping and Returns Policy

We offer express 1 to 2 working day delivery available on all UK Mainland orders (Excluding NI, Highlands & Islands). If you are not satisfied with the product(s) chosen or you have purchased the wrong item(s) you may return them to us within 14 days of receipt excluding custom-made bespoke item(s) which are partially exempt in line with -The Consumer Contracts (Information, Cancellation and Additional Charges) Regulations 2013. An exchange or refund excluding any delivery costs will be offered providing the product(s) are returned complete and in unused perfect condition with the original packaging. If items are returned for these reasons you are responsible for paying the return shipment costs.

Related Products

Our range of 1806 load track also known as Q track, anchor track and loadlok track which most shoring bars fit into available in zinc, stainless steel and galvanised options.

FAQs

How do spring-loaded shoring bars work?

Spring loaded shoring bars work by using tension mechanism that allows the bar to expand and contract, providing a secure fit between cargo tracks, holding loads in place during transit.

What materials are spring-loaded shoring bars made from?

These bars are made from durable materials such as steel or aluminium.

How do I adjust the length of a spring loaded shoring bar?

To adjust the length of a spring loaded shoring bar simply remove the split pin by using either an 8mm bolt or screw driver and gently tap out with a hammer. Then extend or compress the bar to the required length aligning the nearest hole before carefully reinserting the split pin.

Can spring-loaded shoring bars be used with any type of cargo?

Yes, they are extremely versatile and can be used with a wide range of cargo, including pallets, boxes, machinery and other items, as long as the load is spread equally and doesn't exceed the bar’s weight capacity.

How do I maintain spring-loaded shoring bars?

Regularly inspect for wear or damage, clean the bar to remove dirt and moisture, lubricate moving parts as needed, and store in a dry place to prevent rust and corrosion.

-Load-Bar-and-Cups-40mm-x-40mm-360x353.jpg)

-Load-Bar-and-Cups-360x353.jpg)